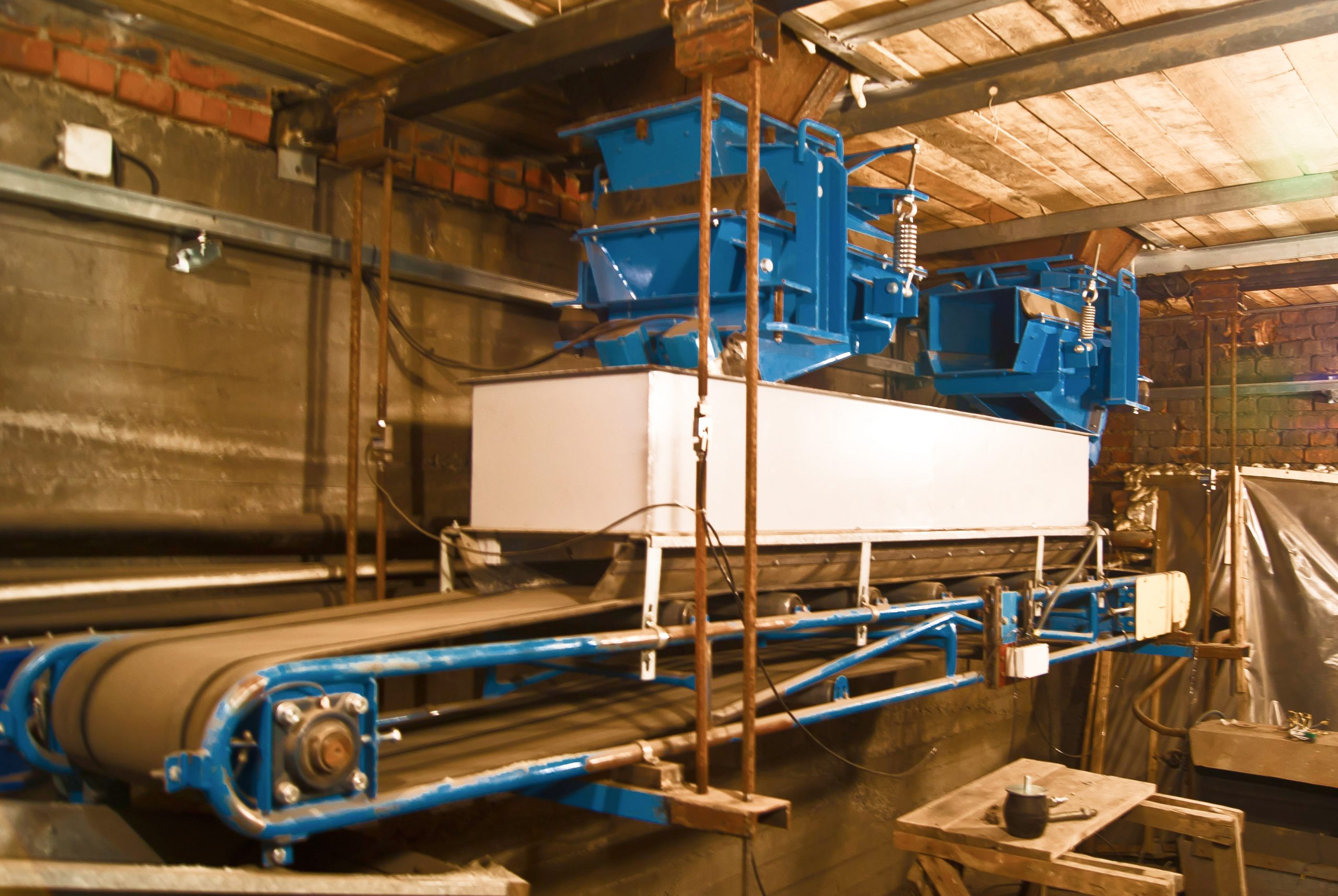

Modification of Hydraulic-Forging Equipment for the Pressed Bricks Manufacture

Project Solution:

It was required for the customer to ensure the operability of the press bricks production line by introducing an automatic control system for hydraulic-forging equipment. The equipment is a hydraulic installation, designed for dry pressing of bricks. Main characteristics:

- category of placement – as required by standard GOST 15150-69;

- operating regime – working and commissioning;

- number of drive hydraulic cylinders – 8;

- number of engines – 2;

- average installed power – 30 kW;

- system pressure – 250 bar;

- supply main – 3 NPE 220/380 V, 50 Hz.

Project Setting:

Throughout this project the following activities were performed:

- design development of the equipment automated control system;

- software development for the equipment;

- production of the automation control cabinet for hydraulic-forging equipment;

- carrying out of pre-commissioning activities on the launch of the automation cabinet for hydraulic-forging equipment control.

Project Result:

- An automation control cabinet for hydraulic-forging equipment ‘GIPPERPRESS’ of the pressed bricks production line;

- Engineering work package for an automation control cabinet for hydraulic-forging equipment ‘GIPPERPRESS’ of the pressed bricks production line: circuit diagrams, wiring diagrams, product certificate, instruction manual, installation software (on CD).

- Circuit diagrams, connections, passport for automation panels and an operating manual.

Other projects

Автоматизация

Установка брикетирования угольной пыли Brecoline

Заказчик: ВаниноТрансУголь (Дальтрансуголь)

Цель проекта: Значительное снижение выбросов угольной пыли и вредных веществ в атмосферу. Улучшение экологической обстановки в акватории порта, возврат до 8% сырья в виде топливно-энергетического брикета.

Срок реализации: 12 мес.

Автоматизация

Модернизация растворобетонного узла

Заказчик: Завод СтройКомплекс

Цель проекта: Автоматизировать контроль и управление работой растворобетонного узла

Срок реализации: 6 месяцев

Автоматизация Lehler - установка орошения отходящих газов вращающейся печи обжига клинкера

Установка орошения отходящих газов вращающейся печи обжига клинкера

Заказчик: Завод Спасс-Цемент

Цель проекта: Разработать систему управления установкой в автоматическом режиме, используя предоставленную производителем Lehler функциональную схему и технологический регламент заказчика

Срок реализации: 8 месяцев

Автоматизация

Система управления наливом нефтепродуктов

Заказчик: ПромЭксГрупп

Цель проекта: Управление процессом налива через панель оператора или АРМа

Срок реализации: 8 месяцев

Автоматизация

Система управления приводом крана 20 тонн

Заказчик: Холдинг ЕВРАЗ

Цель проекта: Разработать проект системы управления мостовым краном 20тонн, режима А8

Срок реализации: 12 мес.

Автоматизация

Система управления наливом нефтепродуктов в автоцистерны

Заказчик: ПромЭксГрупп

Цель проекта: Осуществление налива заданной дозы в автоматическом режиме, с ведением журналов

Срок реализации: 2021

Автоматизация

Система управления дробеметной установки

Заказчик: ВКМ Сталь

Цель проекта: Ввести в эксплуатацию автоматизированную систему управления дробеметной установки

Срок реализации: 2021

12 Case Technological Process Automation

Manufacture of the Germinating Chamber for Soybean

11 Case Technological Process Automation

Development of the Automated Control System for the Packed-Up Ice Cream Production Line

10 Case Technological Process Automation

Development of the Automated Control System for the Defrosting Chamber

2 из 5