Project Setting:

The customer company conducts its business in the food industry and has developed a line of small and medium packaged goods (ice cream). Now, there is a great demand for these products, both in our country and abroad. The existing manufacturing facilities are not equipped with a single automated control system for the production process and are not intended for automatic canning on-line. As a result, the company uses manual labor that does not satisfy the customer’s needs of delivery volume and time.

Project Solution:

- Development, design, manufacturing of hardware-software complex of the automated control system for the packed-up ice cream production line;

- Installation and pre-commissioning of hardware-software complex of the automated ice cream package line.

Project Results:

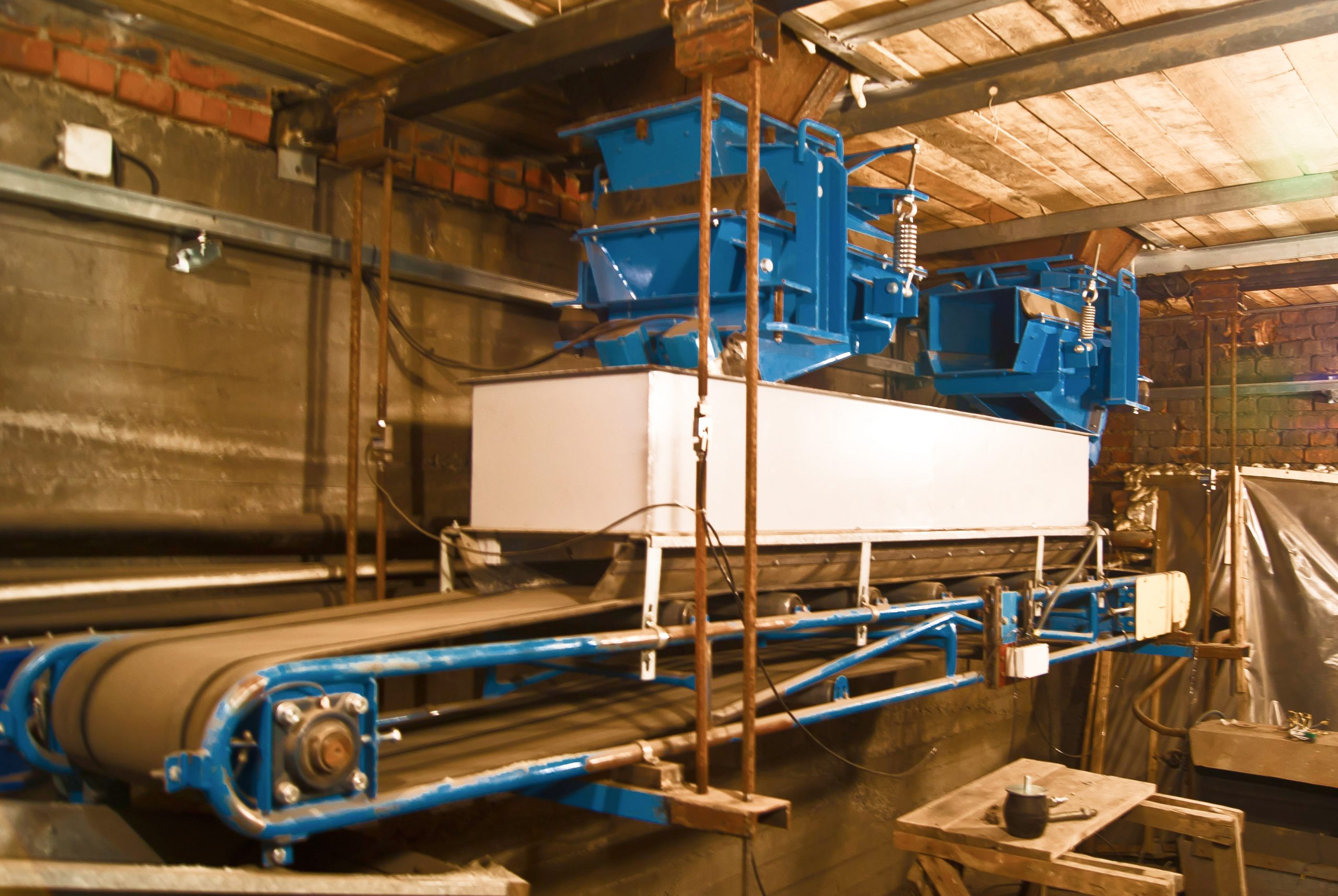

Complex automation ensured the operation of all technological equipment in automatic mode, from preparing of the product to its packaging. The supply of empty packaging to the feed conveyor and discharging of the product from the receiver are not automated. The output of technological parameters to the local network of the enterprise and the Internet for remote control and remote monitoring are provided. The hardware-software complex of the automated ice cream package line includes a control cabinet with a graphic operator panel, a weight conveyor, a control system for the conveyor, freezers, dispensers and auxiliary equipment (booster pumps).